Desiccant Masterbatch - Catalog:

Slogan: Our desiccant masterbatch instead of your drying machine.

Data:

- Active ingredient: Moisture absorbent

- Adding ratio: 0.5-5% (weight basis)

- MFI (g/10min): 0.5-6.5 (±0.15)

- Density (g/cmз): 1.45-1.95 (±0.25)

- Validity: If expose pellets in open air, valid within 8-120hours.

- Application: Absorb moisture. Film / bottle blowing, sheet / pipe extrusion, injection molding.

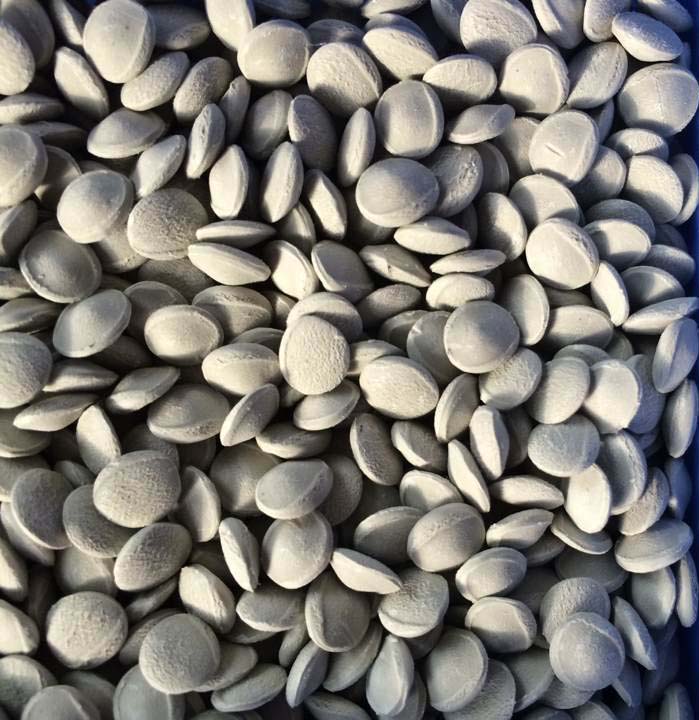

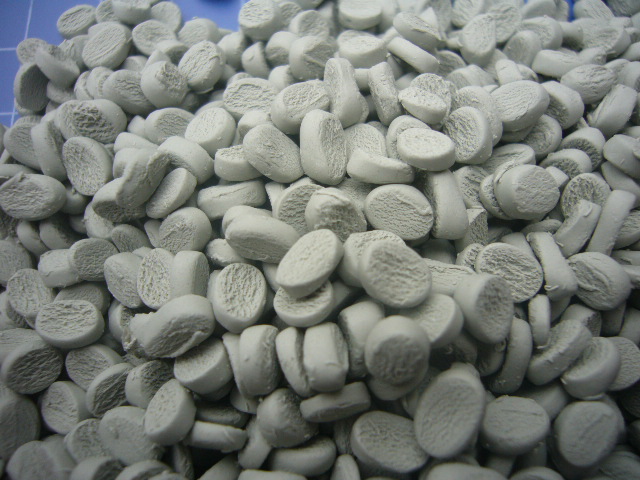

- Pellets: Grey / off white, size molded through Φ6.5 / 4.5 / 3.5mm hole.

- Benefits: Cancel drying process. No weight loss (Because H2O reacts with moisture absorbent, and generates other substance).

hard pellets hard pellets  soft pellets soft pellets

Packing:

- Method 1: Non vacuum (25KG paper bag, 5KG PE bag). 25KG PE bag added as inner package to achieve protective effect as vacuum.

- Method 2: Vacuum (25KG paper bag, 5KG PA bag).

- Method 3: Vacuum (20-25KG paper carton, 5KG PA bag).

- Method 4: 1.5ton/pallet (15ton/20'container).

- Costs: Method 3 > Method 2 > Method 1, Method 4 > loose packing.

- Quality and validity: No difference between vacuum and non vacuum.

- Vacuum bag: Stone-like hardness with potential risk (leakage during conveyance).

paper carton paper carton  wood pallet wood pallet  vacuum bag vacuum bag

Dispersion tests:

- Mix with base resin / additives, expose in workroom for preset hours.

- Blow film consecutively.

- Check filter-sieve mesh (No white residues).

- Check film (No white spots).

- Business is not lottery, we refuse dumping sale to win order.

- We insist on Quality Supreme, Price Moderate, Profit Bottom.

- Keep away from unstable quality with unreasonable price. Otherwise you may have bad experience.

- Dispersibility is top importance. Pictures shown bellow (filter-sieve mesh blocked, residues unmelt):

Validity:

- Valid within 8-120hours if expose pellets in open air.

- Shelf life within 6-12months (after date of manufacture) if well-packed.

- Depend on weather and environment, reference value may change.

- Use up the sooner the better.

- After exposure in open air, start production the sooner the better.

- If invalid (pellet becomes fully white from surface to center), then not use.

- Immediately / tightly repack inner / outer package after unpacking.

- Warehouse in dry place with good ventilation, protect from sunlight / rain.

- Not throw in heavy force. Not step up by foot.

- Labor / forklift's loading / unloading / conveyance as gentle as possible.

- Pallet with protective paperboard / without screw to pierce package.

warehousing warehousing  pellet exposure pellet exposure  forklifting forklifting

Additionals:

- Method of use: Same as color masterbatch.

- If mix materials by blender, then blender without heating-up. Resin / additives with dry surface before / during / after blending.

- If dispense materials by dosing system, then resin / additives with dry surface before / during / after dispensing.

- Adding ratio: Determine by moisture of resin, weather and environment.

- Features: Harmless, no toxin. Conform to SGS standard.

materials materials  auto dosing sieve auto dosing sieve

|

Tips:

- Our Anti Moisture Masterbatch is for elimination of the moisture in recycled PE / PP etc.

- Our Drying / Dehumidifying Additive / Masterbatch is used with polycondensation polymers to omit drying process that is obsolete. Besides nylon, it may be used with other hygroscopic polymers like PET.

- Alias: Named as plastics dessicant masterbatch, dessicant compound, dessicant additive, plastcs dessicants agent, dessicants composite.

|

|